Contact your sales representative and clerk

Product datasheets and safety data sheets

Overview of product stock availability

Educational materials

News about industrial seals

Information on new products and services

Exclusive hints and tips

Fill in your contact details and we will get back to you as soon as possible.

We will call you at your chosen time and advise you on what you need.

Our sales and technical representative will come to your company for a personal consultation.

Its construction is a metal seal in which the sealing part is encased in a metal material. These seals were primarily developed to increase the chemical protection of the internal asbestos filler - Klingerite. The thin sheet, when tightened, replicated the hard Klingerite inside, and a large specific pressure had to be exerted on the seal to ensure a tight joint.

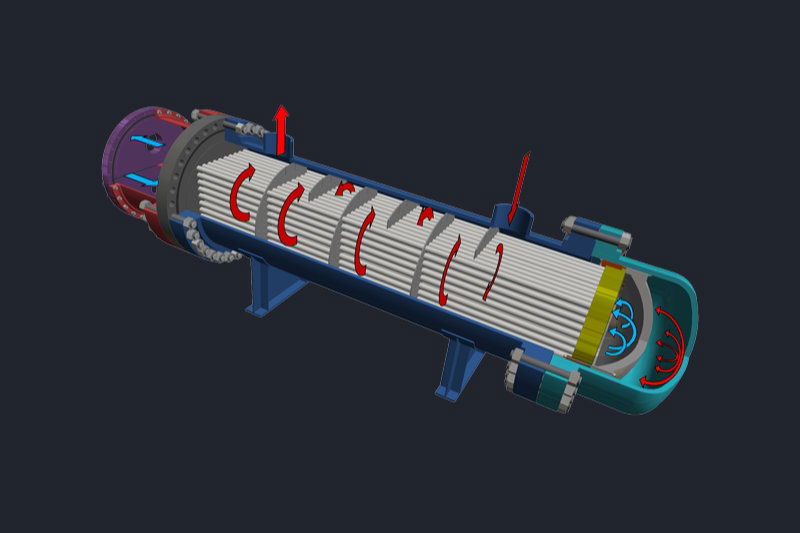

Wrapped gaskets are often used on heat exchangers

With modern gaskets, in which asbestos is replaced by a relatively soft graphite gasket, the thin outer sheet has nothing to rest on and shape itself to when tightened. Combined with the absence of sealing material on the outer surfaces, these seals can be very unreliable, especially during temperature changes.

![DynaGraph]](/files/Articles/800x533_azbest_4.jpg)DynaGraph

From our point of view, the coated seals themselves are already outdated. Nowadays, seals with exactly the opposite construction, i.e. a metal core coated with e.g. graphite on the outer surfaces, are much more widely used. This allows the positive properties of the sealing material to be fully exploited.

In our product range this type of seal is represented by DynaGraph.

![DynaGraph gaskets in position] DynaGraph seal in position

The support part here consists of a corrugated metal core that is covered with flexible graphite of varying density and thickness. The corrugated shape increases the ability to return to its original state and reduces the surface area of the seal at the beginning of tightening. This design provides improved sealing properties over standard gaskets and is well suited for applications that are subject to temperature cycles.

To achieve higher chemical resistance, DynaGraph can also be used in a variant in which the flexible graphite is replaced by PTFE, or the entire seal can be protected by a Teflon envelope, called a shirt.

Pokorny Industries Partnership in quality

© Pokorny industries s.r.o. 2025 - all rights reserved

Made by servisdesign

You don't know what to do?