.jpg?width=352&height=235&aspect_ratio=3:2)

Contact your sales representative and clerk

Product datasheets and safety data sheets

Overview of product stock availability

Educational materials

News about industrial seals

Information on new products and services

Exclusive hints and tips

Fill in your contact details and we will get back to you as soon as possible.

We will call you at your chosen time and advise you on what you need.

Our sales and technical representative will come to your company for a personal consultation.

In the article titled Effect of lubrication on the transmission of forces when tightening a bolted joint we described how friction in the thread and under the nut affects the calculation of the tightening torque and the resulting tightness of the flange connection.

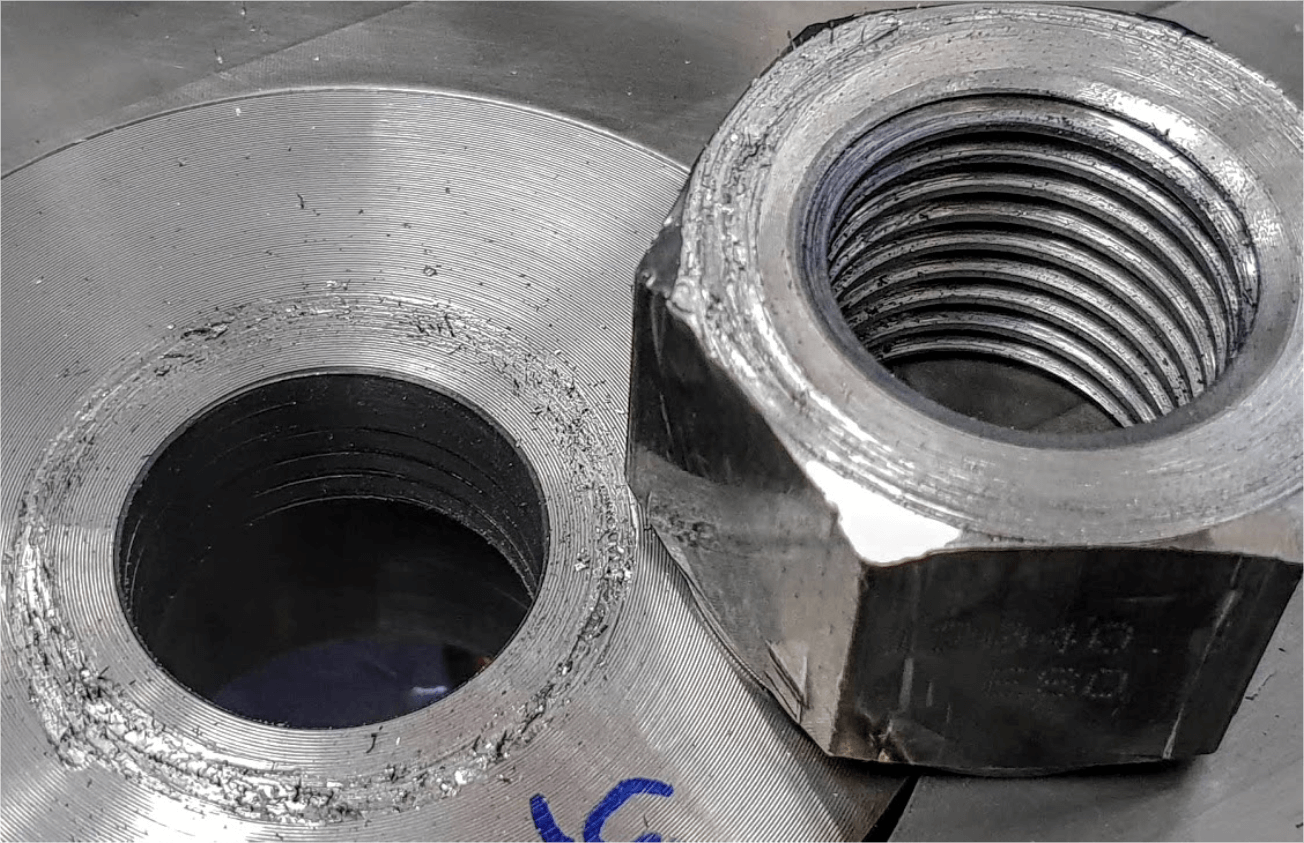

Inherent in this topic is the use of washers under the bolt head and nut. Washers are an integral part of the flange connection just like bolts and nuts. In the points below we explain why this is so.

There are areas between the seating surface of the bolt head (nut) and the flange that affect the resulting coefficient of friction. These are surfaces that may be worn, corroded or otherwise damaged. Thus, when using washers, the surface is clearly defined in terms of hardness and roughness.

It is generally assumed that one third of the total friction in a bolted joint takes place under the nut and the remaining two thirds on the thread.

When calculating the tightening torque, the variance of friction values in the thread (µth), and under the bolt head or nut (µp) must also be taken into account. Increasing variance of these values can result in uneven tightening of the bolted joint.

Care must be taken to ensure that the nut faces and washers are treated with lubricant when assembling the bolted joint.

It is recommended to use lubricants whose friction values (including dispersion) have been measured according to EN 16047. These should be lubricants that minimise friction in the thread and thus reduce the torsional stress on the bolt. These requirements are well met by dry lubricants such as baked-on slip varnish POWERtorque LF kote 450 (See chart with friction ratios in the bolt joint).

Pokorny Industries Partnership in quality

© Pokorny industries s.r.o. 2025 - all rights reserved

Made by servisdesign

You don't know what to do?